20KG Plastic Printed Fertilizer Bucket container

This 5 gallon (18.9 liter) white plastic bucket and pail has your choice of plastic and metal handles.

Made of new polypropylene (PP) plastic.

This kind of tapered design bucket and pail can be used for dry or liquid products and is ideal for food and additives, coatings, paint, feedstuff, detergent, lubricating oil, waterproof building materials, ink and agricultural fertilizer, which meet the demands of customized productions.

Main advantages:

5 gallon (20 liter) capacity

Including plastic handle and metal handle, optional

Tapered design saves space

Labels or patterns can be customized for customers

Proudly Made in China

Additional Information:

Capacity | 5 gal (20 ltr) |

Color | White |

Origin of Materials | PP |

Top Outside Diameter | 295mm |

| Bottom Outside Diameter | 265mm |

Exterior Height | 380mm |

| Net Weight | 1010g |

| Thickness | 1.8mm |

Note: | ** Sold with buckets and lid. ** Available without handle ** Also available in black, clear or natural. Please call for details and availability. |

1.Apply the well-brand new PP material in mass production.

Food grade material, non-toxic and tasteless,strong bearing gravity, fall and pressure resistance, stable leakage prevention and sealing performance.

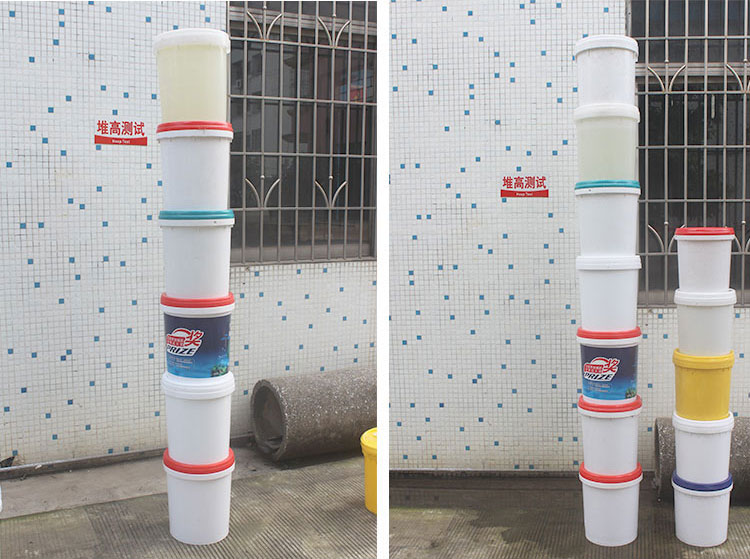

2. Heap height on stacking test

Take six samples of plastic buckets and pails, respectively injected with fully capacity of water, tightly covered, stacked six layers in high, no support on all sides, keep 72 hours then test of stacking.

3. Leak prevention test

Take three samples of plastic buckets and pails, injected with fully capacity of water, tightly covered, keep lying down for 24 house then test of leakage.

4. Drop test

Take three samples, injected with fully capacity of water, tightly covered, and cover the bucket with capacity within 11L, falling height of 1.5m.

If with a capacity larger than 11L, the falling height is 1.2m. Keep the bottom of the plastic buckets and pails almost vertical to the ground, and the lower part of the buckets and pails side impacted on the cement ground parallelly.

Each sample drops 3 times continuously, check after each testing drop, and allow a little amount of leakage at the mouth of plastic buckets and pails during the impact.

5. Aging resistance test

After filling with water on plastic buckets and pails with sealing, dump it or place it vertically for more than 3 months, and check if the performance if effected.

Material:

Polypropylene (PP) is a tough plastic that has good chemical resistance. PP is translucent in its natural state but can have a glossy finish when produced with color.

Some examples of common products made with PP are dairy and medication buckets and pails. Polypropylene is suitable for hot fill applications of up to 165°F and is therefore great for autoclave.

It is not recommended for cold or sub-freezing temperatures.

Disclaimer:

This information has been provided as a general guide. It is the customer's responsibility to select the proper plastic buckets and pails for product and application compatibility.

The CP technology does hereby disclaim any and all warranties, expressed or implied, including any implied warranty or fitness for a particular purpose or use.

We are not responsible for consequential damages arising from customer's selection and use of plastic buckets, pails and label dimensions, and/or closures supplied by us.

1. Apply the well-brand new PP material in mass production.

Food grade material, non-toxic and tasteless,strong bearing gravity, fall and pressure resistance, stable leakage prevention and sealing performance.

2. Heap height on stacking test

Take six samples of plastic buckets and pails, respectively injected with fully capacity of water, tightly covered, stacked six layers in high, no support on all sides, keep 72 hours then test of stacking.