What is the quality standard of 10 litre Fertilizer rubber bucket

As an important container for liquid fertilizer packaging, the quality standard of the 10-liter Fertilizer rubber bucket is directly related to the storage, transportation and

final use effect of the product. The following are the detailed quality standards of the 10-liter Fertilizer rubber bucket in terms of appearance requirements, weight volume,

wall thickness and structure, sealing performance, stacking and safety.

Appearance and quality of fertilizer rubber bucket

Material: The 10-liter fertilizer drum is usually made of high-density polypropylene or other plastic materials suitable for fertilizer storage to ensure its strength and corrosion

resistance.

Wall thickness: The wall of the barrel should have sufficient thickness to ensure the robustness and durability of the barrel body. In general, the thickness of the barrel wall is

adjusted according to the overall design and capacity of the barrel to withstand pressure and wear during normal use.

Appearance: the barrel body should be smooth, flat, no cracks, no bubbles, no impurities, and uniform color. At the same time, the lid should be closely matched with the

mouth of the barrel to ensure tightness.

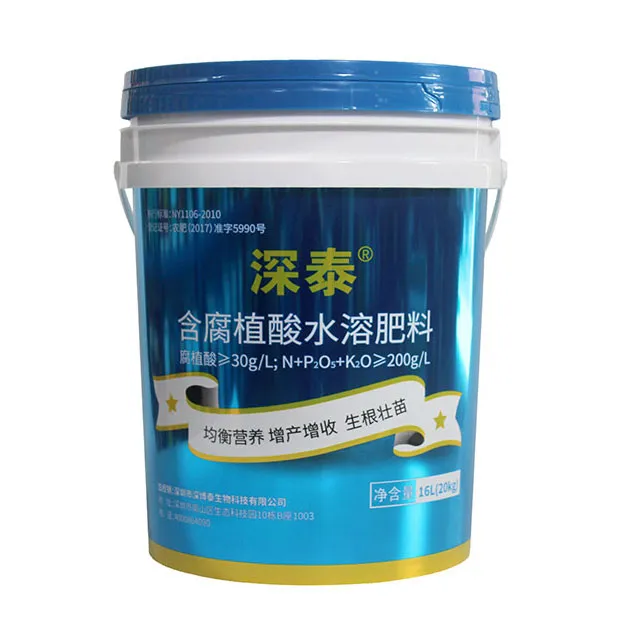

Second, plastic bucket identification and labeling

Net content labeling: The net content of the product should be clearly marked on the body of the fertilizer barrel to ensure that users can accurately understand the amount

of fertilizer in the barrel.

Manufacturer and specifications: The barrel should also be marked with the manufacturer, product specifications and other information, so that users can understand the source

and specifications of the product.

Safety warning: The barrel should also contain the necessary safety warning information, such as "flammable and explosive", "away from the fire source", etc., to ensure the safety

of users during use.

Third, chemical barrel wall thickness and structure

Wall thickness: The wall thickness of the barrel should reach a certain standard to ensure the strength and durability of the fertilizer barrel body. Generally speaking, the thickness

of the barrel wall is not less than 2-3mm, depending on the material and design requirements.

Structure: The design of the barrel should adopt reinforcing bars, convex and concave anchor points and other structures to enhance the impact resistance and stacking performance

of the barrel. At the same time, the bottom of the barrel should be obtuse Angle design, easy to handle and pour material.

Four, circular plastic bucket sealing performance

The sealing performance of the 10-liter Fertilizer rubber bucket is crucial, which is directly related to the storage quality and transportation safety of the fertilizer. Sealing performance

requirements are as follows:

Barrel cover design: The barrel cover should have multiple sealing structures such as oil nozzle, inner plug and anti-theft to ensure that fertilizer will not leak due to lax sealing.

Air tightness test: under standard air pressure (not less than 30kpa), keep for 5 minutes without leakage to ensure the tightness of the barrel body.

5. Stacking and security

Stacking performance: The design of the drum should be easy to stack, and have sufficient strength and stability to ensure that no deformation or rupture occurs during the

stacking process.

Safety performance: The barrel body should be made of high quality materials such as high-density polyethylene, with good chemical corrosion resistance, impact resistance

and drop stacking performance. At the same time, the barrel body should also have anti-theft, anti-counterfeiting and other functions to protect the interests of the manufacturer

from infringement.

5. Other requirements

Environmental performance: pp Fertilizer rubber bucketshould meet the relevant environmental requirements, such as recycling.

Applicable environment: The material of the barrel body should be able to adapt to the environment of fertilizer storage, such as temperature and humidity.

Regular maintenance: Users should regularly check and maintain the fertilizer drum to ensure that it is in good condition.

In addition, in order to ensure the quality of the 10-liter Fertilizer rubber bucket, the manufacturer should also regularly maintain and maintain the production equipment,

strictly inspect and screen the raw materials, and ensure that the products produced meet the relevant standards and requirements. At the same time, in the process of use,

users should also pay attention to regularly check the sealing and integrity of the barrel, timely replacement of damaged or aging barrels, to ensure the safety of fertilizer

storage and transportation. If you need to know more about Chemical bucket in the future, please contact us https://www.cpplasticbucket.com/