What is the corrosion resistance of PP plastic drum?

The anti-corrosion performance of plastic drums is quite excellent, which is mainly due to the material characteristics and production process of plastic drums. The following

is a detailed analysis of the anti-corrosion performance of plastic drums

First, plastic bucket material characteristics

1. Corrosion resistance of plastic drums: Plastic drums are usually made of corrosion-resistant plastics, especially polyethylene (PE) and other polymer materials. These materials

can resist the erosion of a variety of chemical substances, including acids, alkalis, salts, solvents, etc., effectively reducing the damage of chemicals to the plastic barrel body.

2. Chemical stability of plastic drums: Plastic materials such as polyethylene have high chemical stability, which can keep their physical and chemical properties unchanged for a

long time, so as to ensure the stability and safety of chemical substances in plastic drums during storage and transportation.

3. Isolation of plastic drums: plastic drums have good isolation performance, can effectively prevent the penetration of oxygen and water, prevent waste and harmful substances

from escaping. The isolation of plastic drums can avoid the occurrence of chemical reactions, oxidation and corrosion, and further enhance the anti-corrosion performance of plastic

drums.

Second, plastic drum production process

In the production process of plastic drums, advanced processing technology, such as injection molding, blow molding, etc., can ensure the tightness and uniformity of the structure

of the plastic drums. This tight structure and non-porous characteristics make plastic drums better resistant to erosion and damage from the external environment.

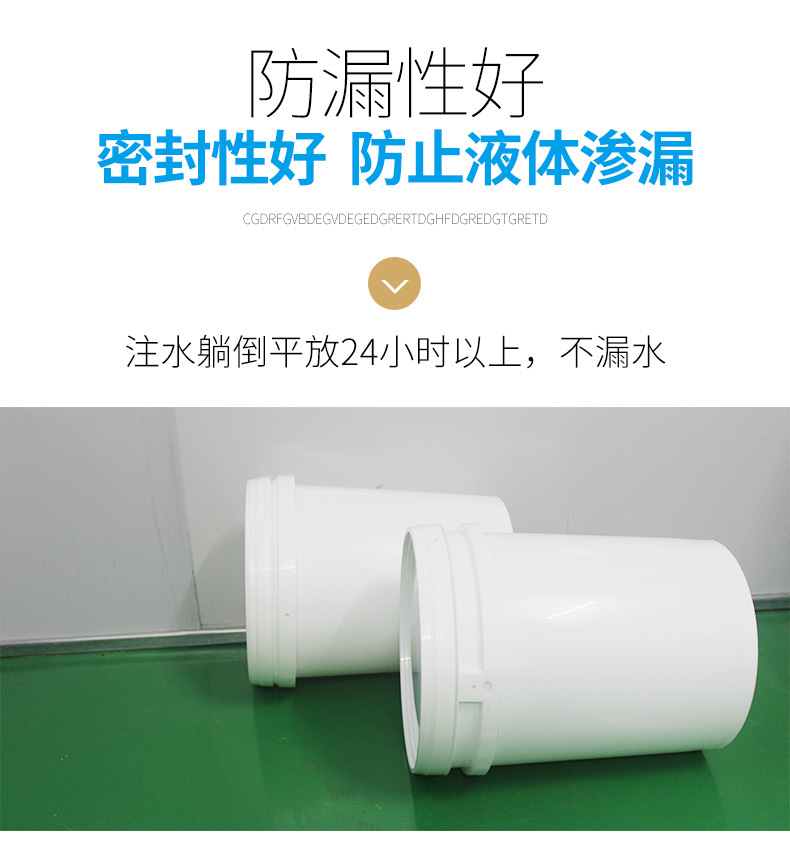

Three, plastic bucket performance test

In order to ensure the anti-corrosion performance of plastic drums, a series of plastic drum performance tests are usually carried out. For example, the plastic drum corrosion test will

place the plastic drum in a corrosive chemical and soak it at a specific temperature for a period of time to see whether the plastic drum body cracks, bubbles or deformation. Through

strict testing, we can ensure that the anti-corrosion properties of plastic drums meet the relevant standards and requirements.

Fourth, the practical application of plastic buckets

Plastic drums are widely used in chemical, pharmaceutical, food and other industries because of their excellent anti-corrosion properties. In these industries, plastic drums are often needed

to store and transport a variety of chemicals and dangerous goods, and plastic drums can provide safe and reliable storage and transportation solutions.

In summary, the anti-corrosion performance of plastic drums is very good, thanks to the material characteristics of plastic drums, production processes and strict performance testing. In practical

applications, plastic drums can meet the storage and transportation needs of various chemical substances to ensure the safety and stability of products.

If you need to know more about plastic drums in the future, you can consult Foshan Eslite Technology Paint Factory, Guangdong Province http://www.gdcpkj.com/