In-mold-labeling

Free to design to service 500+ customers of easy-to-use buckets that grow your market.

It is available options of extremely strong, durable products with a feel of quality and inside protection design.

Customized printed plate roller

Prepare a plate roll for each color of the printed label film separately.

Each printed plate roll is charged as prepayment of USD 80, and the total order reach to 50,000 sets, then the prepayment plate roll charge will be returned.

Label film production

Place the printed plate roll in accordant to the color required for the printing label film, and then print at one time.

The MOQ of customized plate roller is 1000㎡, and the first batch of plate film is charged as prepayment of USD 480, and the charge will be returned after using the plate roller quantity completed.

Label film cutting process

The IML film is set in the injection mold machine by process in high heat or high pressure. Then trim the exterior label film by a die cutter or laser cutting process.

Placed In The Mold

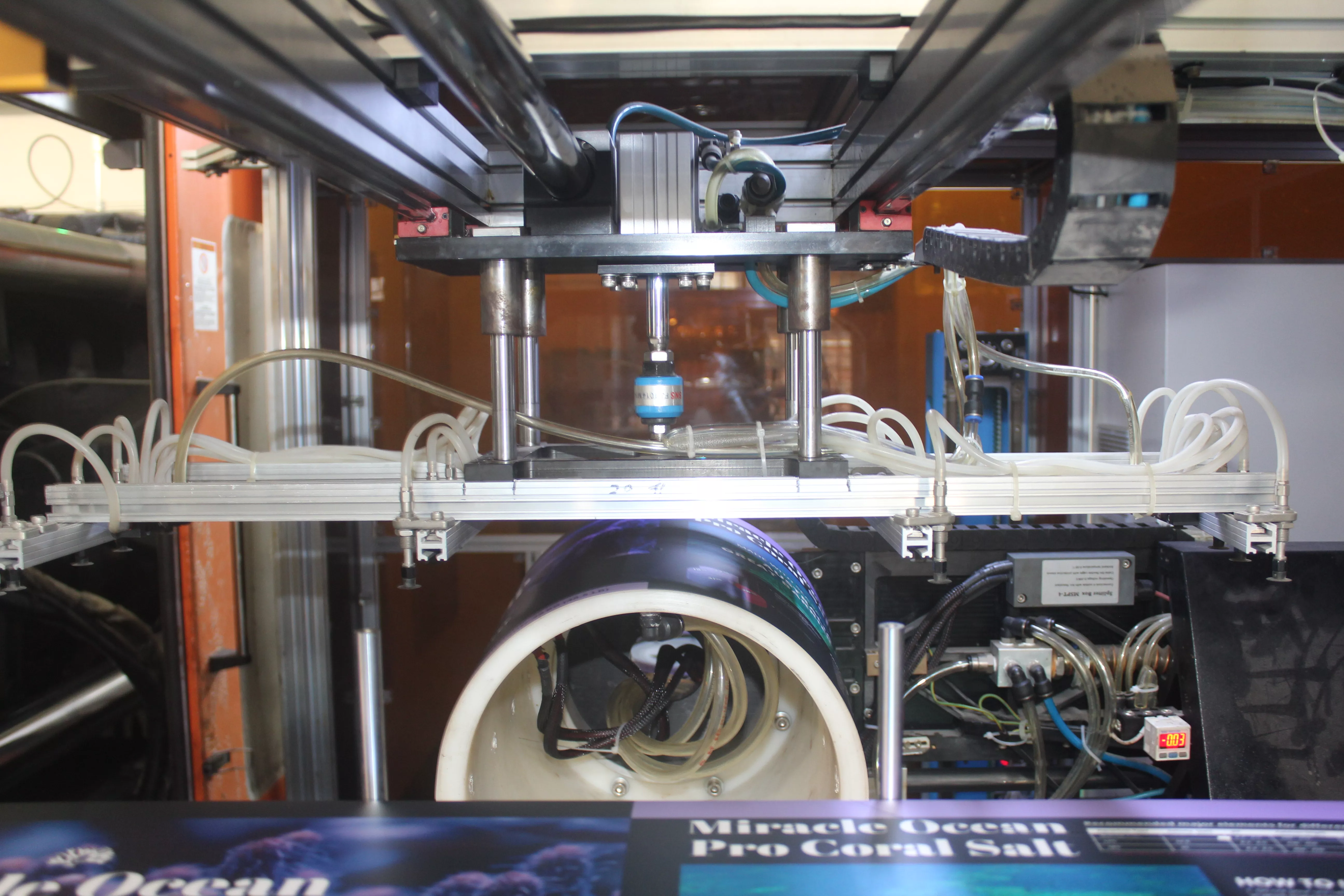

Our factory is with manipulator equipment for plastic bucket production line on In-Mold Labeling process.

The manipulator is accurately carried into the mold tooling.

Finished Product

One-Shot Injection Mould Without Secondary Printing.

In mold labeling (IML) integrated into plastic injections will perfectly solve labeling problems, with a clean, integral look, as the label is perfectly integrated into the product pack itself.